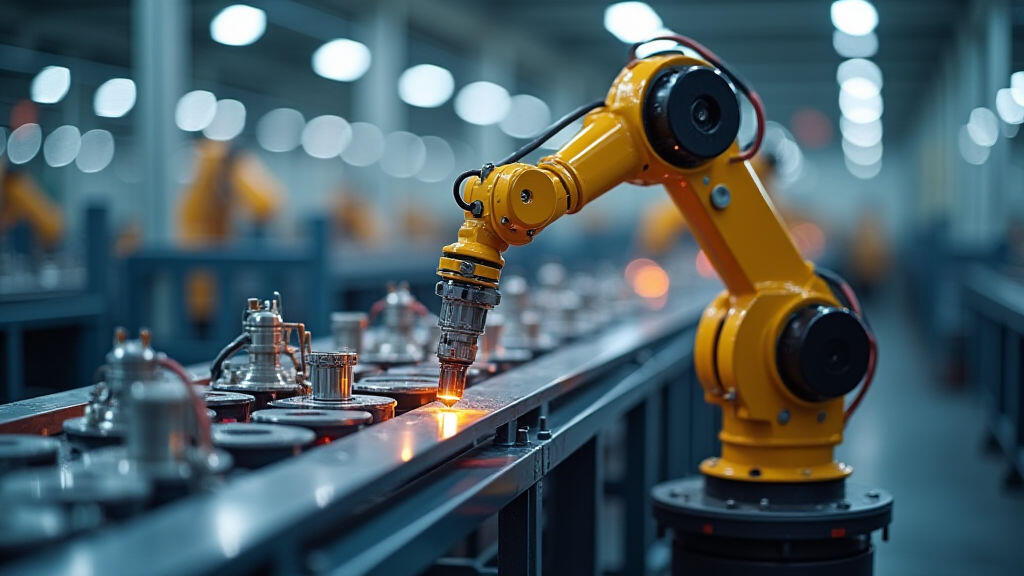

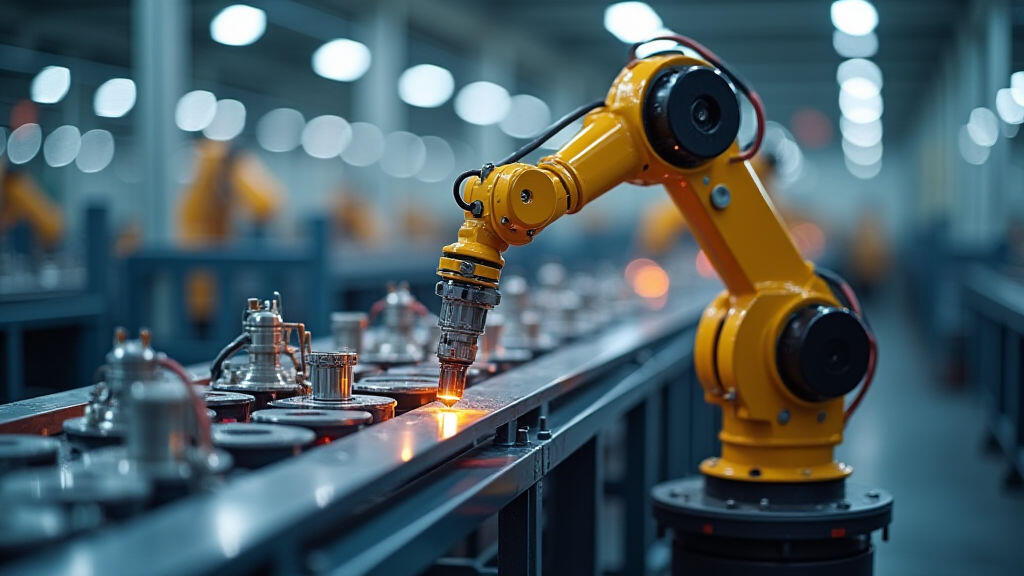

The robotics industry is experiencing explosive growth, fueled by advancements in artificial intelligence (AI), machine learning (ML), and the ongoing push for automation across various sectors. From manufacturing and logistics to healthcare and exploration, robots are increasingly taking on tasks previously performed by humans. A critical, often overlooked, component driving the performance and cost-effectiveness of these robotic systems is the gear motor. Selecting the right gear motor brand is no longer a secondary consideration but a strategic one, directly impacting a robot's efficiency, reliability, and overall bottom line. This article delves into how advanced gear motor technology, specifically highlighting the benefits offered by brands like MES-Drive, can contribute significantly to cost reduction and efficiency improvement in robotics equipment. We’ll explore key considerations, emerging trends, and future potential, all within the context of the current global focus on reshoring and supply chain resilience.

Robots require precise and controlled motion. This is where gear motors come in. Unlike direct-drive motors, gear motors utilize gears to reduce rotational speed and increase torque. This amplified torque is essential for lifting heavy objects, navigating challenging terrains, and executing intricate movements. The gear ratio directly influences the motor's torque and speed characteristics, making the selection of the appropriate gear motor crucial for achieving desired robotic performance. Modern robotics applications demand a wide range of gear motor types, including harmonic drives, planetary gears, and bevel gears, each offering unique advantages depending on the specific application. For example, a robotic arm in a manufacturing setting might benefit from the high precision of a harmonic drive, while a mobile robot navigating uneven ground might require the robust durability of a planetary gear motor.

Cost reduction isn't just about finding the cheapest option. It's about optimizing the system for long-term value. Here's how the right gear motor brand can contribute:

Increased Efficiency: High-efficiency gear motors, like those offered by MES-Drive, minimize energy consumption. This translates to lower operational costs, especially for robots operating continuously. For instance, a robotic warehouse worker making thousands of moves per day can realize significant savings by using an energy-efficient gear motor compared to a standard model. Moreover, higher efficiency also reduces heat generation, lessening the need for cooling systems and extending component lifespan. The rise in energy costs, exacerbated by geopolitical instability, makes this advantage increasingly crucial.

Reduced Maintenance: Reliable gear motors require less frequent maintenance and have longer lifespans. MES-Drive, for example, utilizes advanced materials and manufacturing processes that enhance durability and reduce wear and tear. This reduces downtime caused by repairs, minimizing lost productivity. The trend toward predictive maintenance, leveraging sensor data and AI, further amplifies the benefits of robust gear motors.

Lower Total Cost of Ownership (TCO): TCO encompasses not just the initial purchase price but also factors in energy consumption, maintenance, and replacement costs. By choosing a gear motor with a higher upfront cost but lower long-term operating expenses, businesses can significantly reduce their overall TCO. A detailed TCO analysis should factor in all these elements to make informed decisions.

Improved System Integration: Gear motors designed for seamless integration with robotic systems can reduce development time and assembly costs. Standardized interfaces and readily available documentation facilitate easier integration, minimizing compatibility issues and accelerating project timelines.

Efficiency goes beyond just energy consumption; it encompasses the robot's ability to perform tasks quickly, accurately, and consistently. Advanced gear motor technology from brands like MES-Drive contributes to this efficiency in several ways:

Precision and Accuracy: Harmonic drive gear motors are renowned for their exceptional precision, enabling robots to perform tasks that require fine motor control. This is critical for applications like assembly, pick-and-place operations, and medical robotics.

High Torque Density: Gear motors with a high torque density deliver significant power in a compact size. This allows for the design of smaller, lighter, and more agile robots. The ability to pack more power into a smaller package is particularly important for applications with space constraints.

Reduced Backlash: Backlash, the play or looseness in a gear system, can negatively impact a robot's accuracy and repeatability. MES-Drive utilizes precision manufacturing techniques to minimize backlash, ensuring consistent and predictable motion.

Smooth and Quiet Operation: Low-vibration and low-noise gear motors enhance the overall performance of the robot and create a more comfortable working environment. This is particularly important in applications involving human-robot collaboration.

The recent push for reshoring and diversification of supply chains presents significant opportunities for companies looking to optimize their robotics equipment. Historically, many robotics components, including gear motors, were sourced from overseas. However, geopolitical uncertainties and supply chain disruptions have highlighted the importance of domestic sourcing and stronger partnerships.

MES-Drive, with its commitment to [Insert company's local manufacturing/sourcing initiatives here], offers a reliable and secure supply of high-quality gear motors, reducing reliance on vulnerable global supply chains. Choosing a local supplier also facilitates faster response times, improved communication, and greater flexibility in meeting specific customer needs. This shift towards regionalization offers a competitive advantage in today's challenging market environment.

The robotics industry is constantly evolving, and gear motor technology is keeping pace. Some key trends to watch include:

Integration of Sensors and Electronics: Gear motors are becoming increasingly integrated with sensors and electronics, enabling closed-loop control and enhanced performance monitoring.

AI-Powered Motor Control: AI algorithms are being used to optimize motor control strategies, improving efficiency and responsiveness.

Additive Manufacturing: Additive manufacturing (3D printing) is enabling the creation of custom gear motor designs with optimized performance characteristics.

Sustainable Materials: The development and use of sustainable materials in gear motor construction are gaining momentum, reducing the environmental impact of robotics equipment.

Optimizing gear motor selection is a fundamental element in achieving cost reduction and efficiency improvements in robotics equipment. By prioritizing high-efficiency, reliable, and precision-engineered gear motors from brands like MES-Drive, businesses can significantly reduce their TCO, improve robot performance, and enhance overall operational capabilities. The current global focus on supply chain resilience further underscores the importance of sourcing these critical components from reliable domestic partners. As the robotics industry continues to expand and mature, the role of advanced gear motor technology will only become more pronounced. Staying abreast of emerging trends and choosing the right gear motor partner will be crucial for companies looking to gain a competitive edge in the rapidly evolving world of automation. The integration of AI-powered motor control, coupled with a focus on sustainable materials, promises an even brighter future for gear motor technology and the robotics industry as a whole.

Leave A Reply

Your email address will not be published. Required fiels are marked